Introduction

Workshops involved in the automotive business need high-quality equipment that could offer efficient and safe operations. In New Zealand, the tough automotive industry requires robustness and reliability at every level, so investment in the right equipment for workshops is necessary rather than an option. The paper enumerates the main automotive equipment that New Zealand workshops need, starting from hydraulic lifts to newer technologies like electric vehicle service tools.

Essential Motoring Equipment for NZ Workshops

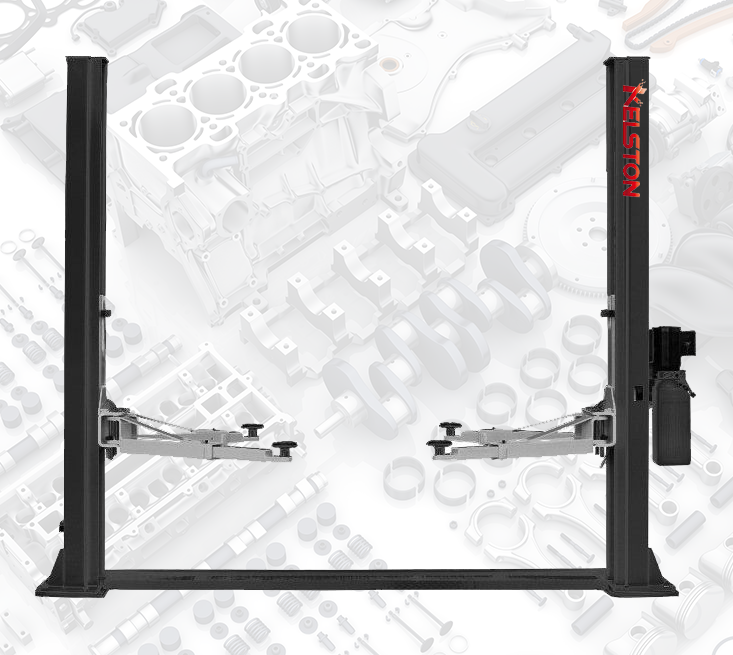

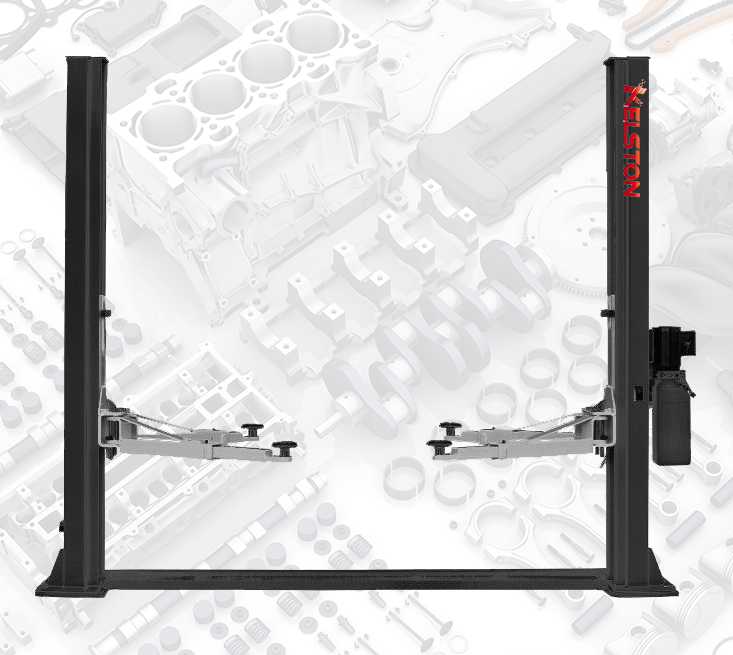

Hydraulic Lifts and Jacks

Hydraulic lifts are indispensable in any workshop, considering the variation in size and weight of the vehicles. They provide the power and flexibility that heavy-duty lifting requires. Floor jacks will also be indispensable because of their speed and convenience, especially for rapid lifting during routine maintenance. Safety features of hydraulic equipment include overload valves that offer protection against excessive load use and stable base constructions that keep the equipment at its appropriate position for operator safety and security of the vehicle being worked on.

Diagnostic Tools

With increasingly sophisticated vehicles, diagnostic tools in the automotive workshop also need to keep pace. Modern scanners diagnose a wide range of issues in a short time to efficiently repair and service a vehicle. Integration of diagnostic tools and technology with the workshop management system will greatly help in improving operational efficiencies.

Tire Service Equipment

It is important to service tires, especially on the diverse and rugged terrain of New Zealand. Basic equipment would revolve around the basic lineup, such as tire changers, wheel balancers, and TPMS tools, which are essential for giving a full service to the tires. Not only does proper maintenance ensure safety, but it also extends the life of the tires.

Hydraulic Press NZ

The hydraulic press is a quintessential tool for every automotive workshop dealing in straightening, bending, and pressing. There are several types and capacities to match virtually each application and requirement. The right hydraulic press greatly enhances the capability to handle diverse repair jobs efficiently.

Air Compressor Systems

Air compressors give life to impact wrenches to spray guns in an automotive workshop. In choosing an air compressor, consideration has to be given to tank size, rating of PSI, output of CFM, energy efficiency, and levels of noise that would suit the needs of a workshop.

Bead Blaster

Bead blasters also do a very effective job in automotive restoration and routine maintenance in paint and rust removal, thereby preparing the surfaces for repair and refinishing. The proper selection of media in conjunction with an understanding of safety precautions will optimize effectiveness while minimizing risks.

Specialty Tools

Other necessary tools in a workshop include brake service equipment, engine hoists, stands, and welding and fabrication tools. These specialty tools tackle only particular tasks, which improve the precision of the service and make it much safer.

New Emerging Trends in Automotive Equipment

Electric Vehicle Service Tools

With the trends of electric vehicles increasingly taking over the market, there is a growing need to have the right servicing tools for such vehicles. This includes specialized diagnostic tools and even battery management systems.

ADAS Calibration Equipment

Advanced Driver-Assistance Systems require highly specialized equipment when it comes to their calibration so that they may function as they ought to. It is in this regard that investment in ADAS calibration equipment will become very necessary for any workshop that aims to provide full service for new vehicles.

3D Alignment Systems

The modern 3D wheel aligner delivers unparalleled accuracy of wheel alignment, which is a key player in ensuring safety and efficiency in the vehicle. The new systems simplify the process of alignment through accurate measurements that will help reduce tyre wear and improve the handling of the vehicle.

How to Choose the Right Equipment for Your NZ Workshop

Equipping the workshop, attention has to be given to specific needs and particular types of serviced vehicles and provided services. Very important is the balancing of the initial cost of the equipment against the long-term benefits while choosing a supplier who provides reliable after-sales support and training.

Conclusion

In fact, investment in the right automotive equipment is going to help in improving efficiency, ensuring safety, and matching demand related to modern vehicle maintenance and repair services. Equipping your workshop with good-quality tool updates and technological advancement developments really ensures that you are safe for long-term success and reliability within New Zealand's competitive automotive servicing industry.